Possibly the worse kept secret....

Moderators: jifflemon, coyote1980, Rachel

Re: Possibly the worse kept secret....

As mentioned in my other thread, James borrowed again to show off on the October meet, and performed faultlessly (I think!).

Still have a list of things to sort:

1) Cooling system; There seemed to be a lack of cabin heat, so I'm thinking coolant flush and thermostat swap. The gauge was reading mid 70's, but with a water cooled turbo, getting heat INTO the system is never going to be a problem, even with a wide open thermostat!

2) Re-hang the exhaust. It's sitting too low, you can see that straight away when following the car! James also provided a new mount but I think, on investigation, they fitted the exhaust with the wrong mounts, which is pushing the backbox too low. So will grab a second mount and sort.

3) Need to sort some squeeks out in the cabin; Aging plastics are great fun eh?

Jaster got a drive of it too, and commented that it felt softer than his GT; So will probably end up throwing some shocks on there at some point too!

Still have a list of things to sort:

1) Cooling system; There seemed to be a lack of cabin heat, so I'm thinking coolant flush and thermostat swap. The gauge was reading mid 70's, but with a water cooled turbo, getting heat INTO the system is never going to be a problem, even with a wide open thermostat!

2) Re-hang the exhaust. It's sitting too low, you can see that straight away when following the car! James also provided a new mount but I think, on investigation, they fitted the exhaust with the wrong mounts, which is pushing the backbox too low. So will grab a second mount and sort.

3) Need to sort some squeeks out in the cabin; Aging plastics are great fun eh?

Jaster got a drive of it too, and commented that it felt softer than his GT; So will probably end up throwing some shocks on there at some point too!

Re: Possibly the worse kept secret....

So, as the final comment above said.....Shocks...

Well, if you're going to do shocks...

may as well follow the old Jeff adage, "Do it once, do it right"

I mean, its a cold miserable December Tuesday, its raining and you've no garage to work in....

So banged the rears on, before I finally conceded that perhaps, it was, in hindsight, not the weather to be working on a 480 in...

Still, productive hour or so!

And also rehung the exhaust whilst I was doing it!

Well, if you're going to do shocks...

may as well follow the old Jeff adage, "Do it once, do it right"

I mean, its a cold miserable December Tuesday, its raining and you've no garage to work in....

So banged the rears on, before I finally conceded that perhaps, it was, in hindsight, not the weather to be working on a 480 in...

Still, productive hour or so!

And also rehung the exhaust whilst I was doing it!

- Jay-Kay-Em

- Advanced 480 rookie

- Posts: 502

- Joined: Tue Nov 27, 2012 10:42 pm

- Location: Huntingdon

- Contact:

Re: Possibly the worse kept secret....

Are they Genuine, Volvo boxed, bottom ball joints?

Can I borrow your time machine!

Can I borrow your time machine!

Jay-Kay-Em

-------------------------------------

Click here for My 480 Turbo Diary

Click here for My Cars

-------------------------------------

Click here for My 480 Turbo Diary

Click here for My Cars

Re: Possibly the worse kept secret....

Nabbed off eBay - Incorrectly listed as track rod ends!Jay-Kay-Em wrote: ↑Tue Dec 17, 2019 9:13 pmAre they Genuine, Volvo boxed, bottom ball joints?

Can I borrow your time machine!

Re: Possibly the worse kept secret....

well the fronts turned out to be slightly more "fun"

N/S first - breezed it in an a couple of hours, with the usual cursing of the idiot that puts 16mm head bolts with 19mm nuts.

For anyone attempting this, a blowtorch is your new best friend. 6 point sockets, rather than 12 point sockets/spanners are a must.

However, the O/S gave me all new sorts of hell....

It started well enough, Pop off the droplink nut, remove the caliper carrier, undo the top strut mounts, undo the lower ones, Spin of the hub nut and pop out the drive shaft.....

Only it didn't....

Not even the tiniest bit...

Drifting the centre with a long punch resulted in zero movement and badly bruised knuckle when I missed.

So, we'll pop the disc off and use a puller to start it.

Only the previous "specialists" who looked after the car have used an impact driver to do the disc screw UP, resulting in one over tightened and severely butchered screw.....

thankfully my foul mood and Mr Hammer soon removed the disc.

Three legged puller on, and the damn thing fought me all the way out....

want to know why'?

See that red stuff on the splines?

That's locktite - not the blue stuff you use for holding bolts in place, the red stuff is Stud and bearing fit. You know, for stuff you DON'T want to come lose ever....

Anyhoo.... soon we had a dead pile of bits...

And you can see how bad the shocks were - Once compressed, they didn't (and still haven't) popped back out!

N/S first - breezed it in an a couple of hours, with the usual cursing of the idiot that puts 16mm head bolts with 19mm nuts.

For anyone attempting this, a blowtorch is your new best friend. 6 point sockets, rather than 12 point sockets/spanners are a must.

However, the O/S gave me all new sorts of hell....

It started well enough, Pop off the droplink nut, remove the caliper carrier, undo the top strut mounts, undo the lower ones, Spin of the hub nut and pop out the drive shaft.....

Only it didn't....

Not even the tiniest bit...

Drifting the centre with a long punch resulted in zero movement and badly bruised knuckle when I missed.

So, we'll pop the disc off and use a puller to start it.

Only the previous "specialists" who looked after the car have used an impact driver to do the disc screw UP, resulting in one over tightened and severely butchered screw.....

thankfully my foul mood and Mr Hammer soon removed the disc.

Three legged puller on, and the damn thing fought me all the way out....

want to know why'?

See that red stuff on the splines?

That's locktite - not the blue stuff you use for holding bolts in place, the red stuff is Stud and bearing fit. You know, for stuff you DON'T want to come lose ever....

Anyhoo.... soon we had a dead pile of bits...

And you can see how bad the shocks were - Once compressed, they didn't (and still haven't) popped back out!

Re: Possibly the worse kept secret....

"breezed it in an a couple of hours, with the usual cursing of the idiot that puts 16mm head bolts with 19mm nuts.

For anyone attempting this, a blowtorch is your new best friend. 6 point sockets, rather than 12 point sockets/spanners are a must."

that's what I use, a 12mm bolt has 19mm hex headed nuts & bolts .. . . I know the bean counters used 17mm AF with integral washer to save time and money, but at least a 19mm you can use the extending wheel-nut tommy bar on (to remove) to tighten only the standard ratchet.

I use the sockets fromm the ALDI impact driver cos they are 'ticht' and nice and beefy if need extra persuassion to be fitted to the head of whatever

For anyone attempting this, a blowtorch is your new best friend. 6 point sockets, rather than 12 point sockets/spanners are a must."

that's what I use, a 12mm bolt has 19mm hex headed nuts & bolts .. . . I know the bean counters used 17mm AF with integral washer to save time and money, but at least a 19mm you can use the extending wheel-nut tommy bar on (to remove) to tighten only the standard ratchet.

I use the sockets fromm the ALDI impact driver cos they are 'ticht' and nice and beefy if need extra persuassion to be fitted to the head of whatever

Alan

480 ES 2litre 'Celebration' ? , C30 1.8ES, SS1

480 ES 2litre 'Celebration' ? , C30 1.8ES, SS1

Re: Possibly the worse kept secret....

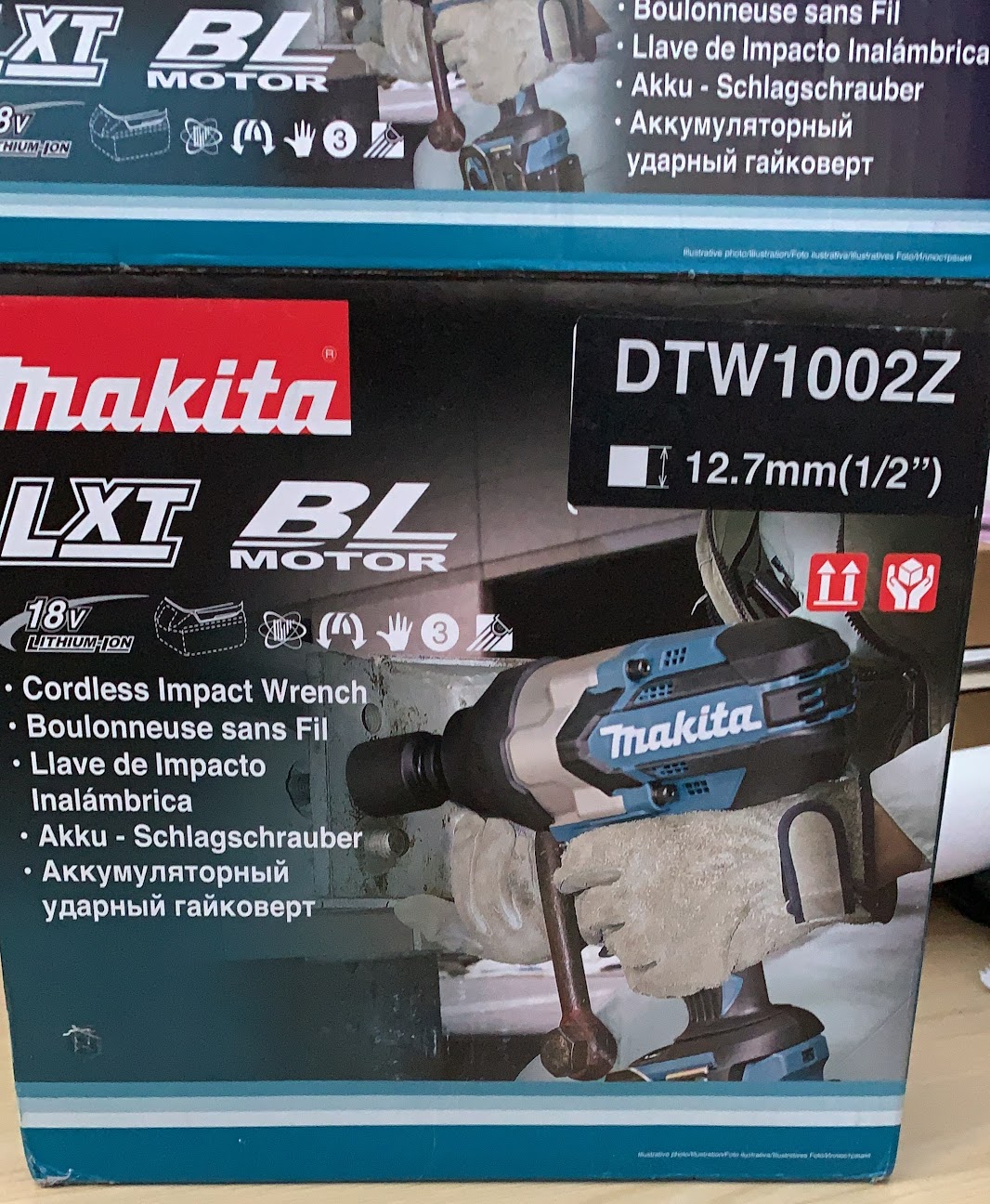

well, lets not forget I've got Doug.....

(Called so because he goes "dougie dougie dougie!" when undoing stuff)

So whilst availability of Torque is never an issue, a 16mm isn't always in an impact socket set and access space for Doug can also be an issue...

(Called so because he goes "dougie dougie dougie!" when undoing stuff)

So whilst availability of Torque is never an issue, a 16mm isn't always in an impact socket set and access space for Doug can also be an issue...

Re: Possibly the worse kept secret....

so, what started out as "flush the heater to see if we can get more heat" has turned into:

Heater matrix removal (and flush)

New Matrix ordered (because £30 is cheaper than risking it not being right)

Front seats removed, and thoroughly cleaned.

which meant the rear seats had to come out and be thoroughly cleaned too...

So I may as well remove all the plastics and add some Cavity wax to the arches (there was some already there, now there's LOADS!)

and give the rear carpet a thorough cleaning too...

which has now got me looking at the front carpet.....

Not really done any pics as we've seen it all before, but I'll do a how-to for the Heater Matrix as we've not got one, and it's as easy doing the pics from "putting it back together stage"

Heater matrix removal (and flush)

New Matrix ordered (because £30 is cheaper than risking it not being right)

Front seats removed, and thoroughly cleaned.

which meant the rear seats had to come out and be thoroughly cleaned too...

So I may as well remove all the plastics and add some Cavity wax to the arches (there was some already there, now there's LOADS!)

and give the rear carpet a thorough cleaning too...

which has now got me looking at the front carpet.....

Not really done any pics as we've seen it all before, but I'll do a how-to for the Heater Matrix as we've not got one, and it's as easy doing the pics from "putting it back together stage"

Re: Possibly the worse kept secret....

Good work, keep it coming - you'll have a perfect 480 that you can put up for sale at many thousands of pounds soon!!

David

David

Current: 1994 480 GT, 1996 460 CD & 1997 440 LE with lots of optional extras & 2007 V50 SE Sport

Previous: Celebration 331 (re-homed with Richard S), Celebration 467 (returned to Martin Mc); Celebration 346 (re-homed with Alan480); Celebration 269 (scrapped abandoned project), Celebration 73 (sold on after 6 years), 1992 ES, 1988 ES - and numerous other non-480 Volvos!

Previous: Celebration 331 (re-homed with Richard S), Celebration 467 (returned to Martin Mc); Celebration 346 (re-homed with Alan480); Celebration 269 (scrapped abandoned project), Celebration 73 (sold on after 6 years), 1992 ES, 1988 ES - and numerous other non-480 Volvos!

Re: Possibly the worse kept secret....

Oh and thought you'd like this....

So I mentioned the Front and rear seats got cleaned; Here's the waste tank of the cleaner...

So I mentioned the Front and rear seats got cleaned; Here's the waste tank of the cleaner...

-

cranna21

- Can tell where the 480 was built

- Posts: 319

- Joined: Sat Jan 11, 2014 3:44 pm

- Location: Aberdeenshire, Huntly

Re: Possibly the worse kept secret....

25+ years of flatulence

'91 480 ES 2.0l 16v 'Williams' Conversion - 212bhp/230nm

'90 940 GL 2.0l Estate

'08 XC90 D5 SE Premium

'90 940 GL 2.0l Estate

'08 XC90 D5 SE Premium

Re: Possibly the worse kept secret....

Oooo I keep forgetting to post about Henry!

Heater matrix - Done - We have heat!

We've also discovered that the Stupid sized fastener brigade have run amok here too.... Make sure you have a 7mm spanner handy is all I'm going to say!

However, After swapping the matrix, I noticed I was losing coolant - Not a lot, but enough for me to worry.

Carpets were repeated prodded and poked, but, no it wasn't the new matrix. Nor the new thermostat/housing.

So..... break out the toy box

So, swap out the cap for a correct size one and pressurise the system. Cap pressure is 1.5 bar apparently, but i'd barely got above a bar and could hear the hiss of escaping pressure. Somewhere nice and easy to get to? This is a 480 you know?

Lights out, nosecone off, shroud off, Jiggled hose, re-tightened clamp and boom, we're holding pressure. Was also nice to discover he's had a replacement rad at some point!

Heater matrix - Done - We have heat!

We've also discovered that the Stupid sized fastener brigade have run amok here too.... Make sure you have a 7mm spanner handy is all I'm going to say!

However, After swapping the matrix, I noticed I was losing coolant - Not a lot, but enough for me to worry.

Carpets were repeated prodded and poked, but, no it wasn't the new matrix. Nor the new thermostat/housing.

So..... break out the toy box

So, swap out the cap for a correct size one and pressurise the system. Cap pressure is 1.5 bar apparently, but i'd barely got above a bar and could hear the hiss of escaping pressure. Somewhere nice and easy to get to? This is a 480 you know?

Lights out, nosecone off, shroud off, Jiggled hose, re-tightened clamp and boom, we're holding pressure. Was also nice to discover he's had a replacement rad at some point!

Re: Possibly the worse kept secret....

When I posted the last update, I didn't know the cap pressure... Having discovered it was actually 1.5bar and I'd only pressurised the system to 1.1, it kinda played on my mind for the last week.....

So out today, and how glad am I i went to the full 1.5 bar?

Horrible one time crimp type clip.

Can't remember if I've mentioned already, but I'm no longer a fan of a jubilee clip; I prefer a Mikalor clamp

Little bit more money, but much better, and even clamping force.

1.5 bar again, and found the tiniest of dribbles from this one... (that's it covered in WD-40, not the leak! The leak was actually travelling down the hose to the low point and dripping from there!)

Final pressurise, and yup, half an hour later (make coffee, drink coffee) we were still holding pressure.

One more thing to stop worrying about.

Whilst I was in the general area, I also did a couple of minor jobs...

Cleaned and greased the battery earth cable were it fastened to the chassis leg

Routed the clutch cable properly.... Seriously, there's clips for the damn thing to use, how can a specialist miss them???

Which also meant the air scoop for the airbox could be refitted....

So out today, and how glad am I i went to the full 1.5 bar?

Horrible one time crimp type clip.

Can't remember if I've mentioned already, but I'm no longer a fan of a jubilee clip; I prefer a Mikalor clamp

Little bit more money, but much better, and even clamping force.

1.5 bar again, and found the tiniest of dribbles from this one... (that's it covered in WD-40, not the leak! The leak was actually travelling down the hose to the low point and dripping from there!)

Final pressurise, and yup, half an hour later (make coffee, drink coffee) we were still holding pressure.

One more thing to stop worrying about.

Whilst I was in the general area, I also did a couple of minor jobs...

Cleaned and greased the battery earth cable were it fastened to the chassis leg

Routed the clutch cable properly.... Seriously, there's clips for the damn thing to use, how can a specialist miss them???

Which also meant the air scoop for the airbox could be refitted....

Re: Possibly the worse kept secret....

So, as many of you already know, I'm a big fan of doing stuff myself. One of the reasons I started in the motor trade was because I spent my first 2 years of motoring being utterly ripped off and shafted by "specialist" garages. There's no magic to servicing a 480 - They come from a special period in history when a lot of the crappy ancient technology (points, carbs and manually adjusting timing) was replaced with electronics, but simple electronics that didn't mean you need to have computer plugged in to tell you what it's latest dilema is.

And so, the other weekend, Henry went in for his MOT. Sometimes I check them over first, but in these Covid times, I was genuinely shocked the station was open, so when they said "come on down", I jumped in a went. It became apparent on the way down that failure was imminent; No washers to the front! And it was, technically, the only thing it failed on. So whilst I could have done the classic "hotswap" (swapping the front and rear motors aroud, these was a classic 480 advisory. "Handbrake efficiency low: requirements just met". So rather than have a pass with advisory, we want a nice clean pass don't we? Plus, with bank holiday weekend approaching, what else was there to do? (yup, guess who forgot about the virtual meet?)

So I though I'd cover all the bases, especially a car this old. Sure, he's got a HUGE wad of service history, but a LOT of that service history was done by "specialists" so it's hard to tell what has been done, and whats simply been added to a bill. Rather than just fix the handbrake and washer pump, it made sense to give it a big thorough service.

And so, the other weekend, Henry went in for his MOT. Sometimes I check them over first, but in these Covid times, I was genuinely shocked the station was open, so when they said "come on down", I jumped in a went. It became apparent on the way down that failure was imminent; No washers to the front! And it was, technically, the only thing it failed on. So whilst I could have done the classic "hotswap" (swapping the front and rear motors aroud, these was a classic 480 advisory. "Handbrake efficiency low: requirements just met". So rather than have a pass with advisory, we want a nice clean pass don't we? Plus, with bank holiday weekend approaching, what else was there to do? (yup, guess who forgot about the virtual meet?)

So I though I'd cover all the bases, especially a car this old. Sure, he's got a HUGE wad of service history, but a LOT of that service history was done by "specialists" so it's hard to tell what has been done, and whats simply been added to a bill. Rather than just fix the handbrake and washer pump, it made sense to give it a big thorough service.

Re: Possibly the worse kept secret....

So, let's start with the ignition. Cap, rotor, Plug leads and plugs are often overlooked in the days of fuel injection. Now whilst none of the above were giving any issues, they're not hugely expensive and simple to change, thus leading to peace of mind.

If you didn't already know, number 1 cylinder is at the gearbox end, number 4 is the cambelt end. I used a Lucas cap and rotor arm (which, once opened, were actually Ducellier, the OEM equipment) and the cap has a cylinder guide on it so you don't have to worry about messing up the plug lead order. Of course, there's nothing wrong in being extra careful and marking your plug leads. Put them to one side for reference.

Cap is held on by three screws - Use a magnetic screwdriver or you'll be guaranteed to be playing "hunt the screw in the engine bay". There's also an earthing strap attached to one of the screws for radio suppression.

Looks like the cap was due a change

Rotor is a press fit - wiggle it and it'll come off.

Renewing the leads is a bit fiddly, if like me you're ever so slightly OCD about fittings and also have a turbo where there's next to zero room!

Circled is the plug wire holder - on the turbo, this is right next to the breather, and is a knuckle scraping, back breaking pain to get the leads into!

On the cap end, follow the diagram (or look at your old cap & leads), but on the turbo, number 1 is roughly at the 10 o'clock position, and going anti-clockwise gives us our 1-3-4-2 firing order.

Leads on, and we're looking nice.

Notice I've not done the spark plugs yet? I like to make sure the car still starts after changing ignition components.

So now were firing, its onto the plugs. One by one, remove the leads. I like to spray a little cleaner around the base of the plug to blast any accumulated dirt away - don't want it falling down the plug hole! (and it's little things like this that you know a specialist should do, but probably doesn't.

Always run new plugs in by hand first - and when you can't reach, a bit of rubber hose on the plug makes a handy tool! the absolute last thing you want to do is cross thread a spark plug! Once in, torque down to 25 to 30N·m (which is 18 - 22 lb/ft in old money)

Air filter?

4 clips on the box, 2 where it connects to the MAF and swap over. If it's particularly nasty in the air box, then give it a vac out. I also check that the cold air feed is actually connected too! New filter in, I fasten the clips on the airbox first, then the MAF.

Next is oil time! So lets fire the engine up and go for a little test drive to see how our new plugs and filters are working. If you can't go for a run because of a lack of MOT, I'd let it get hot enough that the radiator fan has cut in and out a few times.

Whilst I have a clever vacuum suction tool for oil changes, as I've never done Henry's, its old school method. Oil catch pan underneath, sump plug out. It's a renault sump plug which means its a wierd 8mm square drive plug. As I grew up with Renaults, I've always had one, but you can, at a pinch, use a 3/8 square drive extension - Usually better if the retaining ball isn't in it.

If your sump plug has been butchered, you can order new ones from the Bay - It's a standard renault thing, so you could even get a fancy magnet one for less than £8. Where you absolutely do not scrimp on, is the copper squasher washer. As the name suggests, its copper and it squashes. So its a single use item. They're about £1 from a Renault dealer (and I've got loads in stock if you've no dealer nearby!) so why on earth would you try and reuse it? I also go belts and braces and wrap the threads with some PTFE tape.I blame the Years of having to scrub the parents driveway of oil drips

Oil filter is nice and accessible at the front of the engine - Genuine volvo filter for an extra 15bhp. I've mentioned before, but I like to add the date of change with a sharpie to the filter.

5 litres of 10/40w semi synthetic and were good to go. Interestingly, the manual does recommend 15w-40 or 20w-40 "for extreme driving conditions..frequent engine braking on the engine or long stretches of fast motorway driving"

Fuel Filter gets done too; Have covered this previous with a how to, so rather than repeat myself, have a look here. Oh and have a picture of the old one, as a Bosch part number is a handy thing to have.

Auxiliary drive belt is often overlooked too.

Slacken the alternator off at the main mounts (I won't start ranting about the silly spanner sizes...), then crack off, but do NOT remove the pivot bolt. Then slacken the adjuster bolt.(optionally cursing the idiot designer that put it here). Be VERY cautious here not to let it pop out as it's a fiddly nightmare to get back in. Push the alternator down every so often and see if you can remove the old belt from the alternator.

To make your life easier, jack up the O/S and remove the 2 clips and 10mm bolts that hold the splash guard in place. You can now remove the belt quite easily.

I found it easiest to run the belt over the lower power steering pump, then alternator before looping water pump and crank pulley. Copper grease on the pivot bolt and adjuster thread on reassembly.

The old belt wasn't too bad, so thats been kept as an emergency spare (better than no spare!)

Windscreen wipers are another straightforward "one off, one on" replacement. Along with topping up the screen wash with something nice and smelly. Its also good to check that the washer jets put the fluid somewhere useful. Just remember though, that the jets are made of unobtainium! Also check your headlamp washers. This does of course mean you'll have the panic of thinking your pop-ups have failed, before remembering that they don't work with the bonnet up unless you jam a screwdriver into the catch hole! (we've all done it!). Washer pumps just pull out. Fluid is going to go everywhere, but its an excuse to give the reservoir a good cleaning out, as some screenwashes can go gloopy over time.

Rear brakes I've covered before too; However, in this instance, everything was actually perfectly servicable. The low effeciency was due to the previous "specialists" inability to spend £1 on a tube of copper grease, thus the pads had actually rusted themselves onto the carriers and could barely move! A BFH removed them, then with a new set of pads, lots of wire wheeling, judicious use of a some freeze spray to make sure the equally rusty bleed nipples didn't sheer off, the pads were replaced.

Even if you're not replacing the handbrake cables, slacken the central adjuster all the way off and remove the cable end from the arm.

Winding the rear caliper back requires popping the adjuster cap off (and we had one seized cap! Seriously, copper slip people!!) and winding the adjuster back 4 or 5 turns, then using a caliper tool to push the piston back, before doing it all again. I got about 3-4 complete turns before the piston needed pushing back. Once backed all the way, pop on the pads (with copious amounts of copper grease), insert the sliders (red rubber grease) and the anti-rattle spring (copper grease in the ends).

Then, go and jump up and down on the brake pedal at least 10 times. And I seriously mean jump on it! The pressure to the rear brakes gets limited, so you want super hard presses to make the brakes work.

Once we've got the brakes seated, follow the standard handbrake adjustment procedures and you've got a perfect working handbrake.

Just for good measure, I then bled the entire system, starting from the NSR and finishing at the OSF. From the syrup that came out, it was WELL overdue!

So there we are; Nicely serviced,Clean MOT and hopefully trouble free for next year.

If you didn't already know, number 1 cylinder is at the gearbox end, number 4 is the cambelt end. I used a Lucas cap and rotor arm (which, once opened, were actually Ducellier, the OEM equipment) and the cap has a cylinder guide on it so you don't have to worry about messing up the plug lead order. Of course, there's nothing wrong in being extra careful and marking your plug leads. Put them to one side for reference.

Cap is held on by three screws - Use a magnetic screwdriver or you'll be guaranteed to be playing "hunt the screw in the engine bay". There's also an earthing strap attached to one of the screws for radio suppression.

Looks like the cap was due a change

Rotor is a press fit - wiggle it and it'll come off.

Renewing the leads is a bit fiddly, if like me you're ever so slightly OCD about fittings and also have a turbo where there's next to zero room!

Circled is the plug wire holder - on the turbo, this is right next to the breather, and is a knuckle scraping, back breaking pain to get the leads into!

On the cap end, follow the diagram (or look at your old cap & leads), but on the turbo, number 1 is roughly at the 10 o'clock position, and going anti-clockwise gives us our 1-3-4-2 firing order.

Leads on, and we're looking nice.

Notice I've not done the spark plugs yet? I like to make sure the car still starts after changing ignition components.

So now were firing, its onto the plugs. One by one, remove the leads. I like to spray a little cleaner around the base of the plug to blast any accumulated dirt away - don't want it falling down the plug hole! (and it's little things like this that you know a specialist should do, but probably doesn't.

Always run new plugs in by hand first - and when you can't reach, a bit of rubber hose on the plug makes a handy tool! the absolute last thing you want to do is cross thread a spark plug! Once in, torque down to 25 to 30N·m (which is 18 - 22 lb/ft in old money)

Air filter?

4 clips on the box, 2 where it connects to the MAF and swap over. If it's particularly nasty in the air box, then give it a vac out. I also check that the cold air feed is actually connected too! New filter in, I fasten the clips on the airbox first, then the MAF.

Next is oil time! So lets fire the engine up and go for a little test drive to see how our new plugs and filters are working. If you can't go for a run because of a lack of MOT, I'd let it get hot enough that the radiator fan has cut in and out a few times.

Whilst I have a clever vacuum suction tool for oil changes, as I've never done Henry's, its old school method. Oil catch pan underneath, sump plug out. It's a renault sump plug which means its a wierd 8mm square drive plug. As I grew up with Renaults, I've always had one, but you can, at a pinch, use a 3/8 square drive extension - Usually better if the retaining ball isn't in it.

If your sump plug has been butchered, you can order new ones from the Bay - It's a standard renault thing, so you could even get a fancy magnet one for less than £8. Where you absolutely do not scrimp on, is the copper squasher washer. As the name suggests, its copper and it squashes. So its a single use item. They're about £1 from a Renault dealer (and I've got loads in stock if you've no dealer nearby!) so why on earth would you try and reuse it? I also go belts and braces and wrap the threads with some PTFE tape.I blame the Years of having to scrub the parents driveway of oil drips

Oil filter is nice and accessible at the front of the engine - Genuine volvo filter for an extra 15bhp. I've mentioned before, but I like to add the date of change with a sharpie to the filter.

5 litres of 10/40w semi synthetic and were good to go. Interestingly, the manual does recommend 15w-40 or 20w-40 "for extreme driving conditions..frequent engine braking on the engine or long stretches of fast motorway driving"

Fuel Filter gets done too; Have covered this previous with a how to, so rather than repeat myself, have a look here. Oh and have a picture of the old one, as a Bosch part number is a handy thing to have.

Auxiliary drive belt is often overlooked too.

Slacken the alternator off at the main mounts (I won't start ranting about the silly spanner sizes...), then crack off, but do NOT remove the pivot bolt. Then slacken the adjuster bolt.(optionally cursing the idiot designer that put it here). Be VERY cautious here not to let it pop out as it's a fiddly nightmare to get back in. Push the alternator down every so often and see if you can remove the old belt from the alternator.

To make your life easier, jack up the O/S and remove the 2 clips and 10mm bolts that hold the splash guard in place. You can now remove the belt quite easily.

I found it easiest to run the belt over the lower power steering pump, then alternator before looping water pump and crank pulley. Copper grease on the pivot bolt and adjuster thread on reassembly.

The old belt wasn't too bad, so thats been kept as an emergency spare (better than no spare!)

Windscreen wipers are another straightforward "one off, one on" replacement. Along with topping up the screen wash with something nice and smelly. Its also good to check that the washer jets put the fluid somewhere useful. Just remember though, that the jets are made of unobtainium! Also check your headlamp washers. This does of course mean you'll have the panic of thinking your pop-ups have failed, before remembering that they don't work with the bonnet up unless you jam a screwdriver into the catch hole! (we've all done it!). Washer pumps just pull out. Fluid is going to go everywhere, but its an excuse to give the reservoir a good cleaning out, as some screenwashes can go gloopy over time.

Rear brakes I've covered before too; However, in this instance, everything was actually perfectly servicable. The low effeciency was due to the previous "specialists" inability to spend £1 on a tube of copper grease, thus the pads had actually rusted themselves onto the carriers and could barely move! A BFH removed them, then with a new set of pads, lots of wire wheeling, judicious use of a some freeze spray to make sure the equally rusty bleed nipples didn't sheer off, the pads were replaced.

Even if you're not replacing the handbrake cables, slacken the central adjuster all the way off and remove the cable end from the arm.

Winding the rear caliper back requires popping the adjuster cap off (and we had one seized cap! Seriously, copper slip people!!) and winding the adjuster back 4 or 5 turns, then using a caliper tool to push the piston back, before doing it all again. I got about 3-4 complete turns before the piston needed pushing back. Once backed all the way, pop on the pads (with copious amounts of copper grease), insert the sliders (red rubber grease) and the anti-rattle spring (copper grease in the ends).

Then, go and jump up and down on the brake pedal at least 10 times. And I seriously mean jump on it! The pressure to the rear brakes gets limited, so you want super hard presses to make the brakes work.

Once we've got the brakes seated, follow the standard handbrake adjustment procedures and you've got a perfect working handbrake.

Just for good measure, I then bled the entire system, starting from the NSR and finishing at the OSF. From the syrup that came out, it was WELL overdue!

So there we are; Nicely serviced,Clean MOT and hopefully trouble free for next year.

Re: Possibly the worse kept secret....

Good day's work Jeff, and the sort of photo-guide that should enable even the least experienced and most nervous home-mechanic tackle these standard tasks that a garage will charge an arm-and-a-leg for

David

David

Current: 1994 480 GT, 1996 460 CD & 1997 440 LE with lots of optional extras & 2007 V50 SE Sport

Previous: Celebration 331 (re-homed with Richard S), Celebration 467 (returned to Martin Mc); Celebration 346 (re-homed with Alan480); Celebration 269 (scrapped abandoned project), Celebration 73 (sold on after 6 years), 1992 ES, 1988 ES - and numerous other non-480 Volvos!

Previous: Celebration 331 (re-homed with Richard S), Celebration 467 (returned to Martin Mc); Celebration 346 (re-homed with Alan480); Celebration 269 (scrapped abandoned project), Celebration 73 (sold on after 6 years), 1992 ES, 1988 ES - and numerous other non-480 Volvos!

Re: Possibly the worse kept secret....

and that's the reason I do it....

They're surprisingly simple cars to work on (once you've freed all the rusty bits off and got used to the stupid french fixings dept).

Good maintenance will help them last longer. The more that last, the happier I am!

They're surprisingly simple cars to work on (once you've freed all the rusty bits off and got used to the stupid french fixings dept).

Good maintenance will help them last longer. The more that last, the happier I am!

Re: Possibly the worse kept secret....

ref debris around plugs, I use an extension to the hoover, 10mm air line that can be used to remove any last bits of debris from the area around the threads . .. it's OK it is the garage hoover, picked out of a skip about 25 or 30 years ago . . . ..

Alan

480 ES 2litre 'Celebration' ? , C30 1.8ES, SS1

480 ES 2litre 'Celebration' ? , C30 1.8ES, SS1

Re: Possibly the worse kept secret....

Finally (more for me than an one else), here's the part numbers of the trickier stuff to find:

Drive belt - Gates 6PK1153 (powersteering, no AC)

Fuel Filter - Bosch 0 450 905087

Plugs - NGK ZGR5B

Cap - Lucas DDB248

Rotor - DRB243C

Drive belt - Gates 6PK1153 (powersteering, no AC)

Fuel Filter - Bosch 0 450 905087

Plugs - NGK ZGR5B

Cap - Lucas DDB248

Rotor - DRB243C

Re: Possibly the worse kept secret....

I'm sure the more regular visitors to the forum know that I work in somewhat bizarre and random ways, so I thought I'd share the thought process behind the latest bit of work on Henry.

It started with this: the knob fell of the radio.

The cassette flap had been missing for a while too, so it made a lot of sense to simply replace it. And Thus... down the rabbit hole we went. How far?

Well, I sourced a very nice Philips DC712 - Think of it as the cassette version of the Celebration radio.

There it is fitted. No more rabbit hole right?

So very, very wrong.

You see, the radio can run a CD changer, and they can be had quite reasonably now, so I'll have both options.

Now to fit both the radio and the associated CD changer wiring, the dash would have to come out. So whilst the dash is apart, it'd be rude not to repair the flakey speedo face and put one of my repaired dash surrounds on.

Oh, I can't fit the changer in the "usual" spot, as Henry has the rare boot liner option, so I figured I'd mount it elsewhere.

Which meant the interior would have to come out.

So whilst the interior was out, it made sense to add some soundproofing.

And if I'm soundproofing, I may as well drop the headlining, so that I can do the roof and sort the drooping headliner.

And whilst I've easy access, I could finally replace the seat belts....

And that, dear forum friends, is how you go down the rabbit hole!

It started with this: the knob fell of the radio.

The cassette flap had been missing for a while too, so it made a lot of sense to simply replace it. And Thus... down the rabbit hole we went. How far?

Well, I sourced a very nice Philips DC712 - Think of it as the cassette version of the Celebration radio.

There it is fitted. No more rabbit hole right?

So very, very wrong.

You see, the radio can run a CD changer, and they can be had quite reasonably now, so I'll have both options.

Now to fit both the radio and the associated CD changer wiring, the dash would have to come out. So whilst the dash is apart, it'd be rude not to repair the flakey speedo face and put one of my repaired dash surrounds on.

Oh, I can't fit the changer in the "usual" spot, as Henry has the rare boot liner option, so I figured I'd mount it elsewhere.

Which meant the interior would have to come out.

So whilst the interior was out, it made sense to add some soundproofing.

And if I'm soundproofing, I may as well drop the headlining, so that I can do the roof and sort the drooping headliner.

And whilst I've easy access, I could finally replace the seat belts....

And that, dear forum friends, is how you go down the rabbit hole!